Original four talk youth Blanche investment research

Pulp research front pull a little long, this issue mainly introduces the pulp brand, paper types and a little paper cost composition, micro water.

Six, the demand direction of the pulp

China's demand for commercial needle pulp / hardwood pulp accounts for about 35% of the world, and it is the world's largest demand for commercial pulp. In addition, western Europe and North America account for 22% / 17% and 23% / 9% respectively.

First of all, the main brands of wood pulp in China are:

·

The drift needle pulp brand is mainly imported from Canada, the United States, Chile, Russia and Finland, and the domestic drift needle pulp brand is mainly for Yunnan Yunjing Forest paper production.

·

·

Common floating pulp brands are mainly imported from Brazil (goldfish, parrot), Indonesia (acacia, eagle brand), Chile (star) and Russia (Bukuo), domestic floating pulp brands are mainly produced by Hainan Jinhai, Shandong Asia-Pacific Senbo brand and Zhanjiang Chenming produced by the Chenming brand.

·

·

According to the report of the futures company, according to the domestic name can be divided into one, two, three types of pulp.

·

o

A kind of pulp: such as Canada's north wood, golden lion brand, mainly produced in the northern forest of Canada, slender fiber, high paper strength.

o

o

Two types of pulp: such as Canada's Kelp, moon, horse brand, Finland's Finland and Europe brand, belong to the northern drift needle pulp, quality is slightly worse than a kind of pulp.

o

o

Three types of pulp: such as Chilean Silver Star Pacific, the United States IP, Russian black needle cloth needle, Swedish Blue forest and other brands, the quality is slightly worse than the second type of pulp.

o

Secondly, waste paper is divided into national waste and foreign waste. Developed countries have a perfect waste paper recycling classification system, waste paper treated quality is high, large-scale recycling effectively reduce the production cost. Domestic waste paper recycling classification is backward, the overall quality of waste paper is low. Before, China mainly imported two categories of waste paper pulp:

·

Pulp board (including wet pulp, loose pulp, etc.), mainly from Taiwan, Southeast Asian countries, mainly by Liwen, Sun, Nine Dragons and other large factories in foreign direct factories or cooperative production. In 2016 and before, about 40% of the domestic demand for waste paper was met by imported waste paper. In 2017, China introduced a policy to limit waste waste, and China's foreign waste imports continued to decline. In 2021, the import of waste paper has been completely banned.

·

·

Roll pulp, mainly from North America, Southeast Asia, South Asia and other countries, this kind of products is similar to finished paper (often known as scrambled paper, garbage paper, etc.), both as paper, but also as pulp, used to be the focus of the customs inspection object, often into the finished paper tariff.

·

In addition, there are non-wood pulp such as bamboo pulp, sugarcane pulp, grass pulp, etc., used in household paper, paper pulp molding products, construction, furniture, etc.

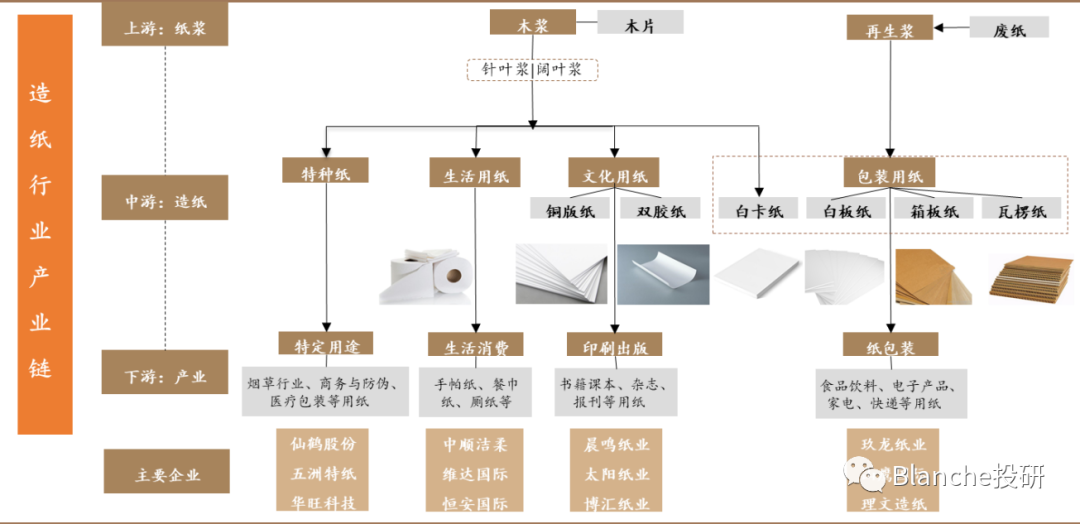

Seven, the downstream paper classification

Next, we will introduce the classification of the downstream paper species, First of all, a simple understanding of the process of paper making: pulp after pulp, grinding, pulp to achieve the performance of the pulp, Then dehydrthe pulp through the web and form the page, Mechanical mechanical then further ates the wet paper further (low energy), Then further dehydration (high energy consumption) and improve the performance of the paper (paper strength and smoothness), The adhesive part will change the surface properties of the paper (water resistance, strength, etc.), After improving the smoothness, gloss and uniformity of the paper by pressing the light, If you need to coat, the coating machine to improve the paper performance (uniformity, printing performance, etc.), Finally, by rolling the paper format into a paper roll, Complete the paper-making.

The higher the stiffness of paper, the less pulp, the more calcium carbonate, the more flexibility of paper, the more pulp, the lowest cost of white card paper. In paper making, broad-leaved pulp and coniferous pulp are 7:1 relationship, with dry pulp. Chenming paper industry low cost advantage is because the pulp is less a dry pulp link, out of the wet pulp directly paper.

Paper classification: according to raw materials, paper can be divided into pulp and paper and waste paper: pulp and paper includes special paper, household paper, cultural paper and white paper; waste paper includes box board, corrugated, whiteboard and other packaging paper.

Photo source: Deppon Securities Research Institute

(1) pulp and paper system: special paper, household paper, cultural paper and white card paper

·

Special paper: it is the general term of paper species with special use and small output, such as carbon paper, edible paper, water-soluble paper, etc., used in tobacco, business, medical packaging, etc. The leading enterprises are Xianhe Stock, Wuzhou special paper, Jiawang Technology.

·

·

Household paper: the main downstream is toilet paper, facial tissue, handkerchief paper, napkins, diapers, etc., the annual consumption is not obvious seasonal. Leading enterprises for shun Jirou, Weida national standard, Hengan International.

·

·

Cultural paper: used for printing and writing, it mainly includes newsprint, non-coated cultural paper and coated cultural paper.

·

newsprint: it is generally roll paper, paper media consumption is not good, gradually declining.

·

Coated cultural paper: including coated paper is also called powder paper. The surface is coated, printed more bright colors, common fashion magazines, posters, picture albums, most of the consumption is flat paper, a small part of the roll paper. Single copper paper is mainly used for making wine labels, cigarette packs, etc., the annual tobacco and alcohol peak season in March and June, October and December. The main applications of double copper paper include illustrations of advanced books and periodicals, brochures, commodity advertisements, calendars, etc. The factors affecting consumption including YQ and electronic market also have an impact. The spring fair in March and April and the promotion before September and December make the use of leaflets large, but the seasonality has gradually weakened in recent years. Copperplate paper has basically formed a stable competition pattern, APP (43%), Chenming (19%), Sun (12%), Huatai (10%), CSR concentration is high.

·

Not coated culture paper: including offset paper, double tape, downstream for books, teaching materials, etc, mechanical pulp not coated paper mainly refers to the overpressure paper SC (only drum), chemical pulp not coated including printing paper copy paper, etc., the main audience for students and office, demand is relatively rigid, long-term demand and enrollment, education, demographic dividend relationship, short-term cyclical, 3-may students autumn teaching material stock, 9-December students spring textbook stock has a lot of demand, in addition series of domestic major economic and political events will have periodical publishing order demand. There is still room for improvement in the concentration of double adhesive industry, including Chenming (17%), Sun (12%), Huatai (5%) and Nine Dragons (4%).

·

·

White card paper: a kind of fiber organization is relatively uniform, surface layer with packing and adhesive composition and surface coated with a layer of paint, used to print business cards, invitations, trademarks and packaging decoration. The main downstream is carton, paper card, paper bag, etc. Usually, 100% bleached wood pulp is used as raw material, sulfate chemical coniferous wood pulp is used in the surface layer and bottom layer, and the core layer uses broad-leaved wood chemical mechanical pulp. After the slurry, calcium carbonate, barium sulfate and other fillers are added.

·

(2) Waste paper system: box board, corrugated, whiteboard and other packaging paper: express logistics presents the Spring Festival month low, then rose month by month, reaching the highest value of the year at the end of the year.

·

Box board: also known as kraft paper or cow card paper, packaging household appliances, daily necessities, Chinese and western medicine packaging, etc., now the hot demand is e-commerce and express delivery. Paper manufacturers enjoy strong bargaining power in the waste paper purchase industry chain, and paper enterprises reduce costs by lowering the purchase price of waste paper raw materials.23-25 annual capacity expansion plans are more, focusing on Longtou Mountain Eagle International and Nine Dragons Paper, as well as Liwen Paper.

·

·

Corrugated: corrugated board is the raw material of corrugated core, after corrugated machining, fiber combined strength, a certain elasticity, made of cartons with shock and pressure resistance.618. For online shopping activities, the main downstream demand of corrugated box board comes from food and beverage, daily chemicals, automobile, express delivery, electronic appliances, express delivery and other industries.

·

·

White board: is a kind of front is white and smooth, the back is mostly gray bottom cardboard, high water content, generally about 10%, can be made into packaging boxes, design, handmade products, etc.

·

Eight, paper pulp consumption and cost

Pulp price decision paper enterprise cost, and affect the paper price and enterprise profit space, such as the sun paper raw material cost accounted for more than 70%, special paper leading crane stake raw material cost accounted for about 68%, the upstream pulp enterprises have strong voice in the industrial chain, pulp enterprise gross margin is significantly higher than papermaking enterprises, the upstream pulp factory leading is enjoy beautiful beautiful profit, to the downstream price transmission ability is stronger.

The pulp composition used in each paper has different characteristics and proportion, resulting in different costs. According to the content of Zijin Tianfeng Futures, the raw material composition of each ton of paper products is as follows:

·

Cost composition of papermaking: pulp cost + electricity + steam + raw material cost (manufacturing financial artificial auxiliary, etc.)

·

·

Electricity bill: a ton of paper needs about 500-700 kilowatt-hours of electricity

·

·

Steam: a ton of paper requires 1.7 tons of steam (also 300 degrees / ton), the cost of steam is different.

·

·

The industry range of raw material external cost is above 1700-2000.

·

·

Some cost-saving operations: equipped with alkali recovery and thermoelectric devices to reduce energy consumption and auxiliary costs, or self-produced slurry greatly reduce the cost of raw material.

·